Products We Offer

Our company offers a comprehensive portfolio Ultra-High Performance Concrete (UHPC) that encompasses Glass Fiber Reinforced Concrete (GFRC), Glass Reinforced Plastic (GRP), and Glass Fiber Reinforced Gypsum (GFRG) products. And Ultra-High Performance Concrete (UHPC). We take immense pride in our expertise in crafting urban street furniture from these materials, delivering functional and aesthetic marvels that transform public spaces.

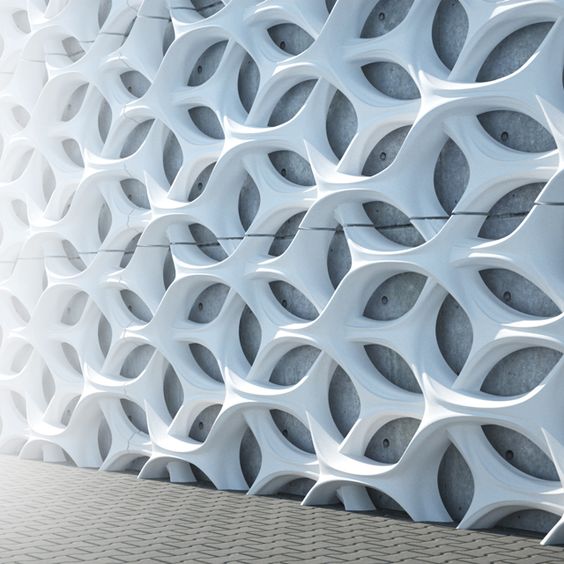

Ultra-High Performance Concrete (UHPC)

Ultra-High Performance Concrete (UHPC) is an advanced, high-strength concrete designed for superior performance in demanding applications. It offers exceptional durability, mechanical strength, and resistance to environmental factors.

UHPC combines advanced materials technology with aesthetic and structural versatility, making it a preferred choice for architects, engineers, and builders.

High Compressive Strength: Exceeding 150 MPa, suitable for load-bearing structures.

Enhanced Durability: Resistant to abrasion, impact, and chemical attacks.

Flexural Strength: Withstand bending forces for enhanced design possibilities.

Reduced Porosity: Minimizes water absorption and ensures long-term resilience.

Versatile Applications: Ideal for bridges, facades, precast elements, and more.

Glass Fiber Reinforced Concrete (GFRC)

Glass Fiber Reinforced Concrete (GFRC) is a composite material that incorporates glass fibers into a concrete mix. It offers several advantages over traditional concrete and can be particularly beneficial for projects requiring lightweight, durable, and versatile building materials.

Lightweight: Significantly lighter than traditional concrete.

High Strength: Enhanced tensile and flexural strength.

Durable: Resistant to cracking, weathering, and corrosion.

Glass Fiber Reinforced Polymer (GFRP)

It is a composite material made of high-strength glass fibers embedded within a polymer matrix (usually a thermosetting plastic like vinyl ester, epoxy, or polyester). It is also known as fiberglass or glass reinforced plastic (GRP).

GFRP is engineered to replace traditional steel reinforcement in concrete structures due to its superior properties:

Corrosion Resistance: Unlike steel, GFRP does not corrode, making it ideal for harsh environments and extending the lifespan of structures.

High Tensile Strength: GFRP has excellent tensile strength, often exceeding that of steel.

Lightweight: It is significantly lighter than steel, which reduces transportation and handling costs and the dead weight of structures.

Non-Conductive: GFRP does not conduct electricity or heat, making it suitable for applications near electrical equipment or where thermal insulation is needed.

Durable: It has a longer lifespan and higher fatigue resistance compared to steel, reducing the need for frequent repairs and maintenance.

Glass Fiber Reinforced Gypsum (GFRG)

It is a composite building material made from calcined gypsum plaster reinforced with glass fibers. It is also sometimes known as Rapidwall.

GFRG panels are typically manufactured in thicknesses like 124mm and can have hollow cavities that can be filled with reinforced concrete for increased strength.

Composition: Made of gypsum plaster, glass fibers, and sometimes additives like water repellent emulsions.

Lightweight: GFRG is significantly lighter than traditional concrete or brick.

Strength: When filled with reinforced concrete, GFRG panels have substantial strength and can act as load-bearing walls and shear walls resistant to lateral loads from earthquakes and wind.

Street Furniture Segment

Street furniture refers to objects and pieces of equipment placed on streets or sidewalks for public use. These can include items like sitting benches, arroe benches, bins, bollards, streetlights, fountains, and other elements that enhance the functionality, safety, and aesthetics of urban spaces.